Roll casting

Material information

Our engineers use load calculations to develop the optimum material selection for your requirements.

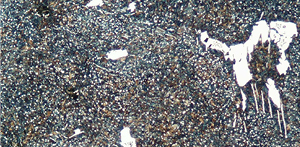

Sub- and near-eutectoid cast steel

Depending on the carbon content, finely distributed carbides are embedded in the pearlitic to bainitic matrix. Products in this material group are always tempered and have high strength and fire crack resistance.

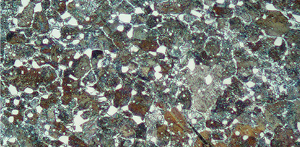

Hypereutectoid cast steel

Pearlitic matrix with a more or less pronounced carbide network depending on the carbon content and finely distributed carbides in the matrix. These materials are characterised by high wear resistance and, in the case of free graphite, good grip. Products in this material group are always quenched and tempered.

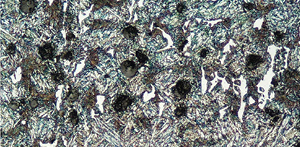

Perlitic ductile iron

Pearlitic matrix in which carbides in a ledeburitic arrangement - decreasingly from the outside to the inside - and - increasingly graphite in spherical form - are embedded. The wear resistance increases with increasing hardness.

Azicular ductile iron

Bainitic matrix in which carbides in a ledeburitic arrangement - decreasingly from the outside to the inside - and - increasingly graphite in spherical form - are embedded. In addition to the carbides, the bainitic matrix formed by alloying acts as a second factor in reducing wear.

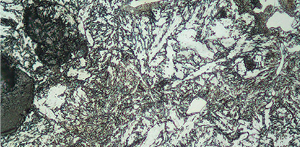

Hard casting with graphite-free working layer

The ledeburitic working layer contains perlite and carbide. Towards the inside of the piston, the carbide is increasingly replaced by free graphite so that the core of the piston contains no carbide.