Hand mould casting

Industrial mills and grinding systems

COSWIG GUSS develops and manufactures a wide range of components for grinding systems that can withstand extreme mechanical loads. Europe's leading mill manufacturers rely on the engineering and industry expertise of COSWIG GUSS.

For our customers, we work hard to increase the tool life of industrial mills, extend their lifespan, and maximize productivity. To this end, the engineers at COSWIG GUSS develop innovative and high-strength materials - even far beyond DIN standards. This is how we secure lasting competitive advantages for our partners.

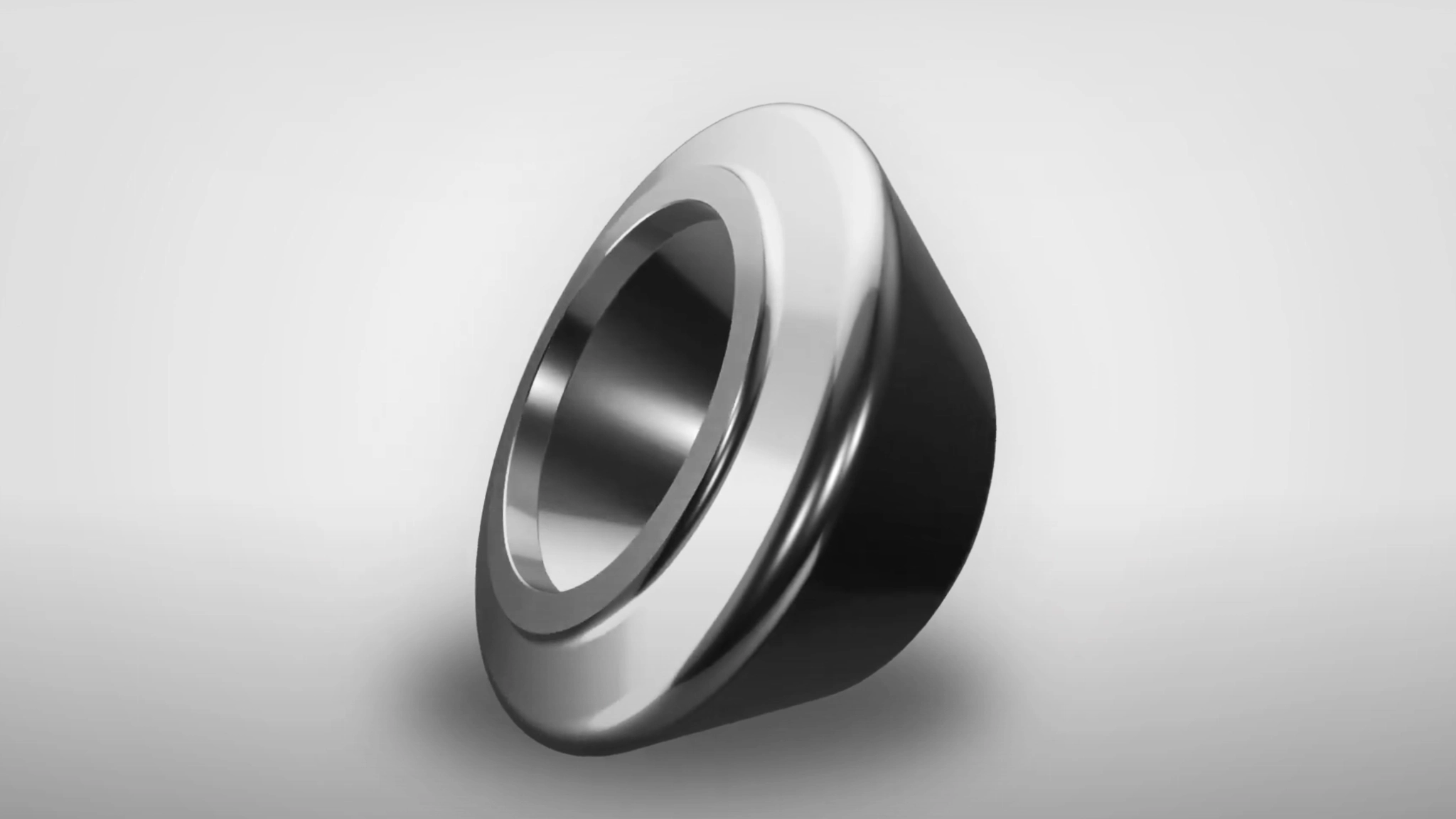

Our customers can also count on maximum reliability when it comes to casting and machining. For initial castings, COSWIG GUSS carries out extensive casting and solidification simulations before the start of production. This reduces development costs and increases safety. With 120 years of experience, state-of-the-art machinery and specialized skilled workers, COSWIG GUSS guarantees the highest quality. Castings such as roller bodies, bearing blocks, locating bearing housings, levers, forks, roller shells, grinding plates, bearing covers, pressure beams, power frames and grinding tables only leave the factory when every detail meets the high standards.

Our quality management system is certified in accordance with the currently valid DIN EN ISO 9001.

Overview of services

-

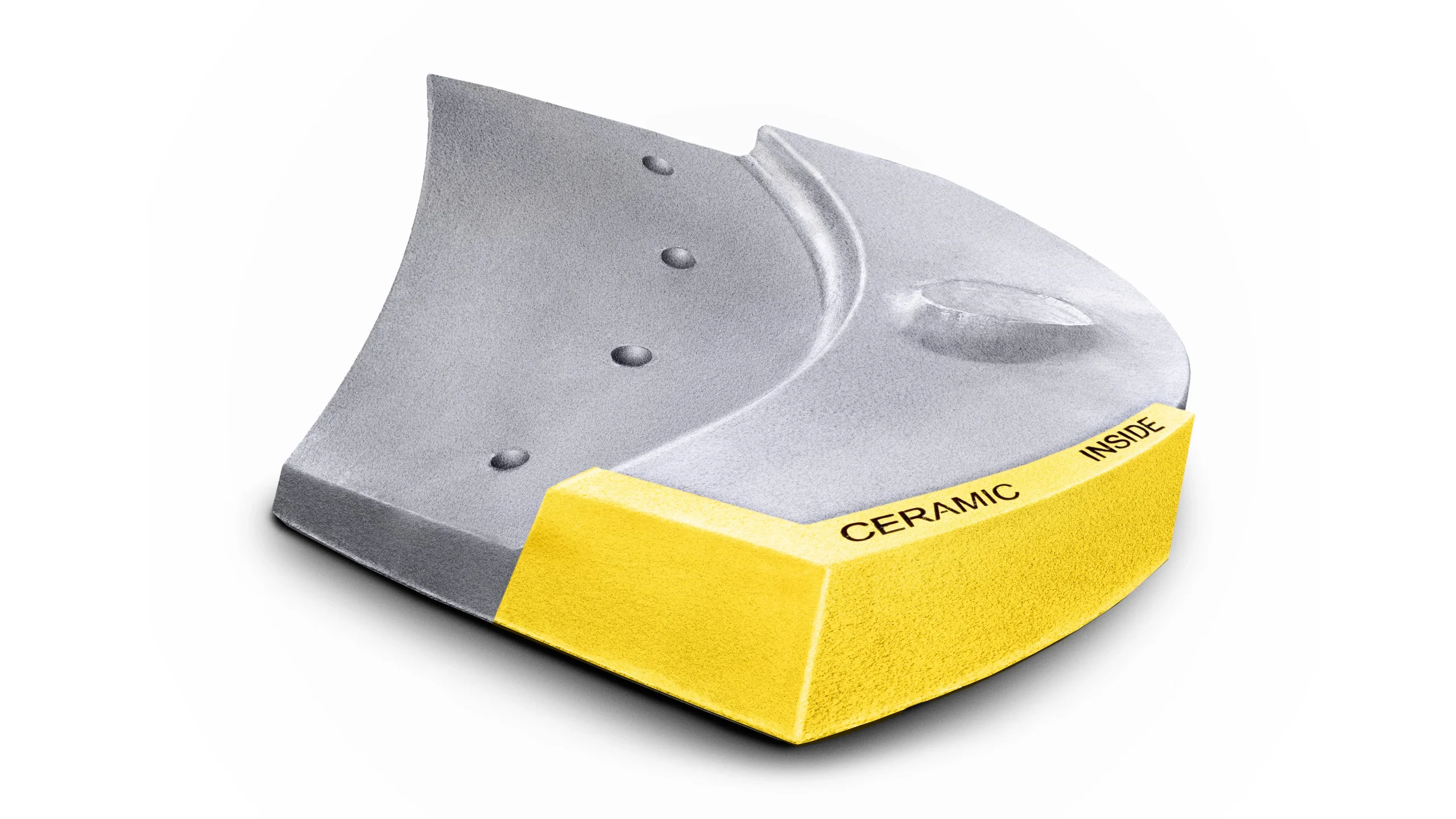

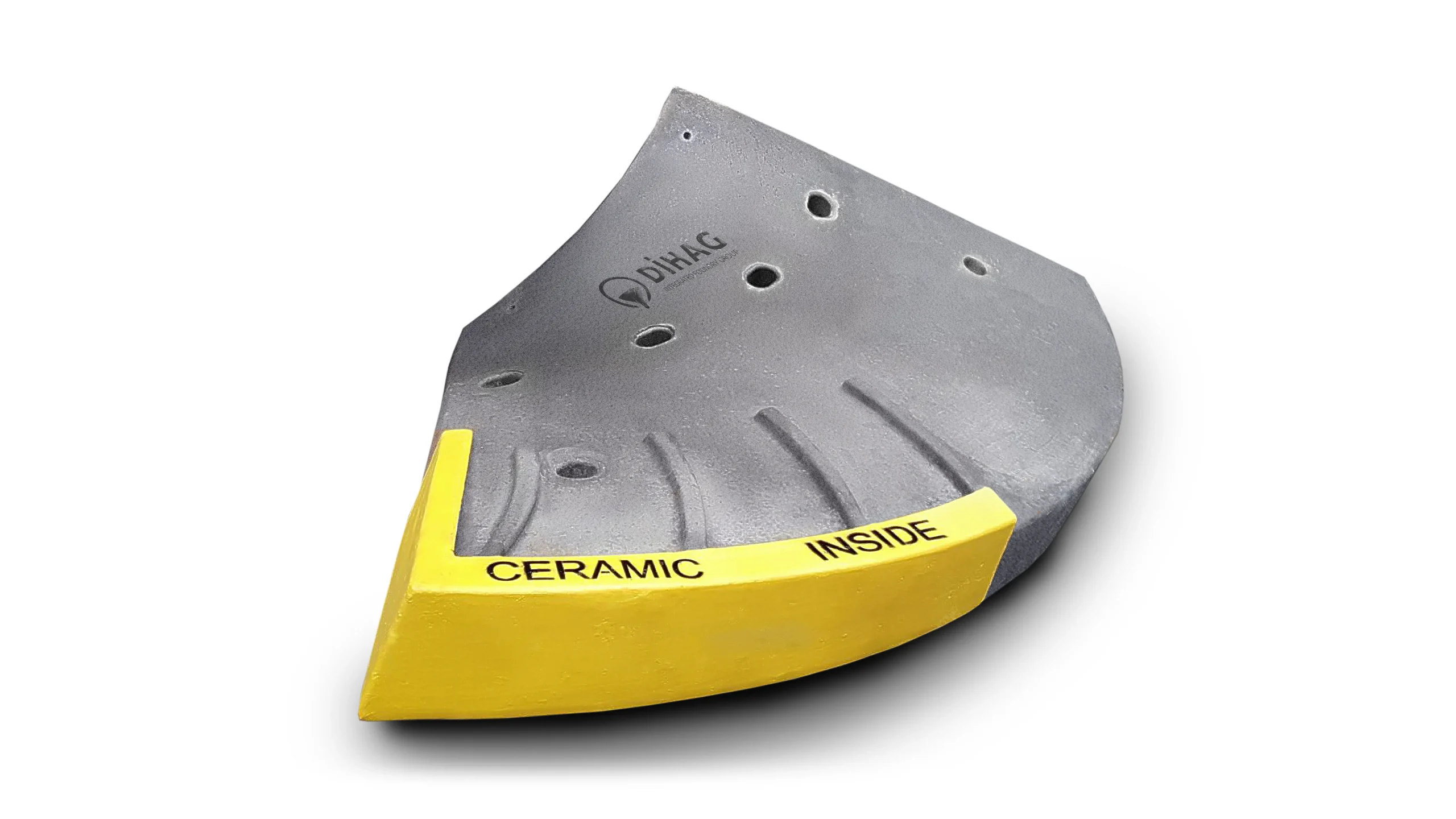

Co-development of a casting-compatible design and production of various components for the grinding process

-

Use of a wide variety of materials depending on the requirement for high wear resistance, strength or toughness

-

Casting and solidification simulation, especially for first castings

-

Pre-machining/finishing on CNC/NC machines

-

Coloring according to customer requirements