History

Innovation as tradition

From a small ironworks to one of the most modern foundries in Europe - in its 125-year history, COSWIG GUSS has constantly developed itself and the casting process.

COSWIG GUSS has been merging traditional craftsmanship and modern technologies since 1892. With passion, experience and a spirit of research, we have pushed the boundaries of what is possible, mastered new challenges and won over new customers. Our high standards and our demanding customers are constantly driving us forward. Today, we produce and develop customized castings in our high-performance plant. We are one of the leading international suppliers in the manufacture of rolls and special components for wind turbines, industrial mills and printing machines.

But we are not resting on our laurels. We grow with our tasks. Then as now, COSWIG GUSS continues to research innovative concepts to make our products, processes and materials that little bit better. Join us on this journey into the future.

Milestones in the company's history:

2021

Investment in a double-girder overhead crane for Foundry I with a lifting capacity of up to 95 tons

2016

Development of a hollow rotor shaft made of solid solution strengthened cast iron

2015

Introduction of the high-chrome material (EN-GJN-HB555 - X Cr 14)

Investment in a further CNC high-performance lathe

2014

Introduction of solid solution strengthened cast iron (EN-GJS-450-18 and EN-GJS-500-14)

2013

Investment in a Leica 6DoF high-performance laser tracker

2012

Development and commissioning of an automated water tempering system for rolls

2011

Introduction of the new material NiHard (EN-GJN-HB555)

Investment in a further CNC high-performance lathe

2010

Delivery of hollow rotor shafts for the first German offshore wind farm »alpha ventus«

2009

Construction of a new foundry for hand mould casting at the Coswig site

Investment in two new annealing chambers and a CNC vertical lathe

2008

Investment in a further CNC high-performance lathe and a band saw

2007

Expansion of mechanical processing including air-conditioned measuring room

Development and test castings of insert bodies for fuel rod final storage containers (until 2012)

2006

New foundry hall with annealing chambers and a new roll forming shop

bis 2005

Further extensive investments in mechanical processing and foundry

2003

Development and production of prototypes of the hollow rotor shaft for the world's first 5 MW wind turbine

2000

Establishment of an in-house research and development department

1996

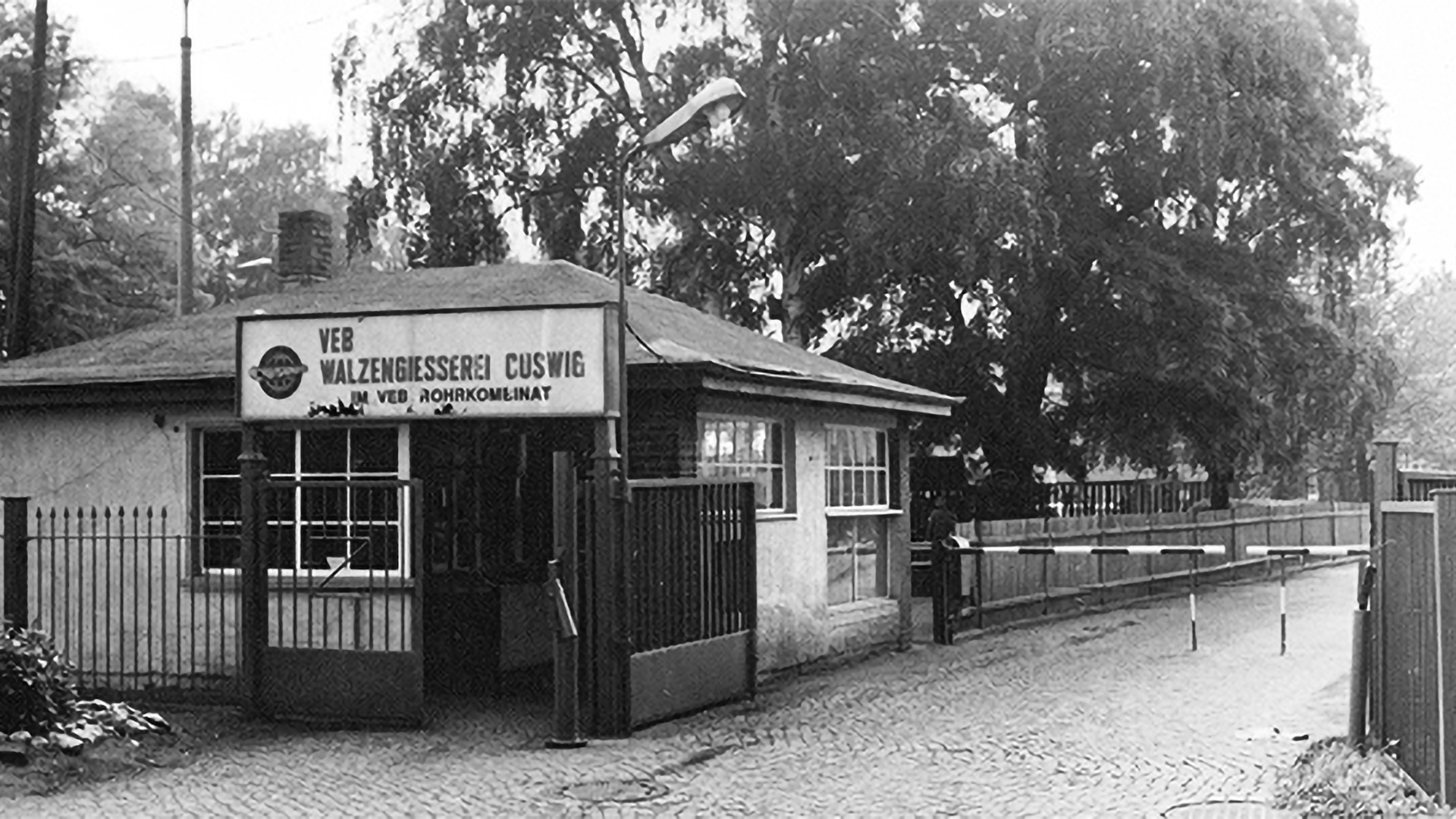

Takeover of Walzengießerei Coswig GmbH by the DiHAG group of companies

1995

Commissioning of the new medium-frequency induction furnace melting plant

1994

Start of production of components for mill construction

1993

Start of production of hand mould castings

ab 1967

After the production of segments for salt and copper mining was discontinued, the supply of printing cylinders to the Planeta Radebeul printing press plant began

1963

Commissioning of an 18-tonne electro-melting furnace and thus the development of steel rollers as well as the resumption of segment production

1946

After the end of the war, dismantling of the facilities as part of reparations, start of production of chilled cast iron rolls and, for the first time, rolls for hot rolling mills

1922/23

Expansive development through the construction of a modern machine moulding shop, the metal foundry with 3 melting furnaces, a new turning shop and an administration building

ab 1919

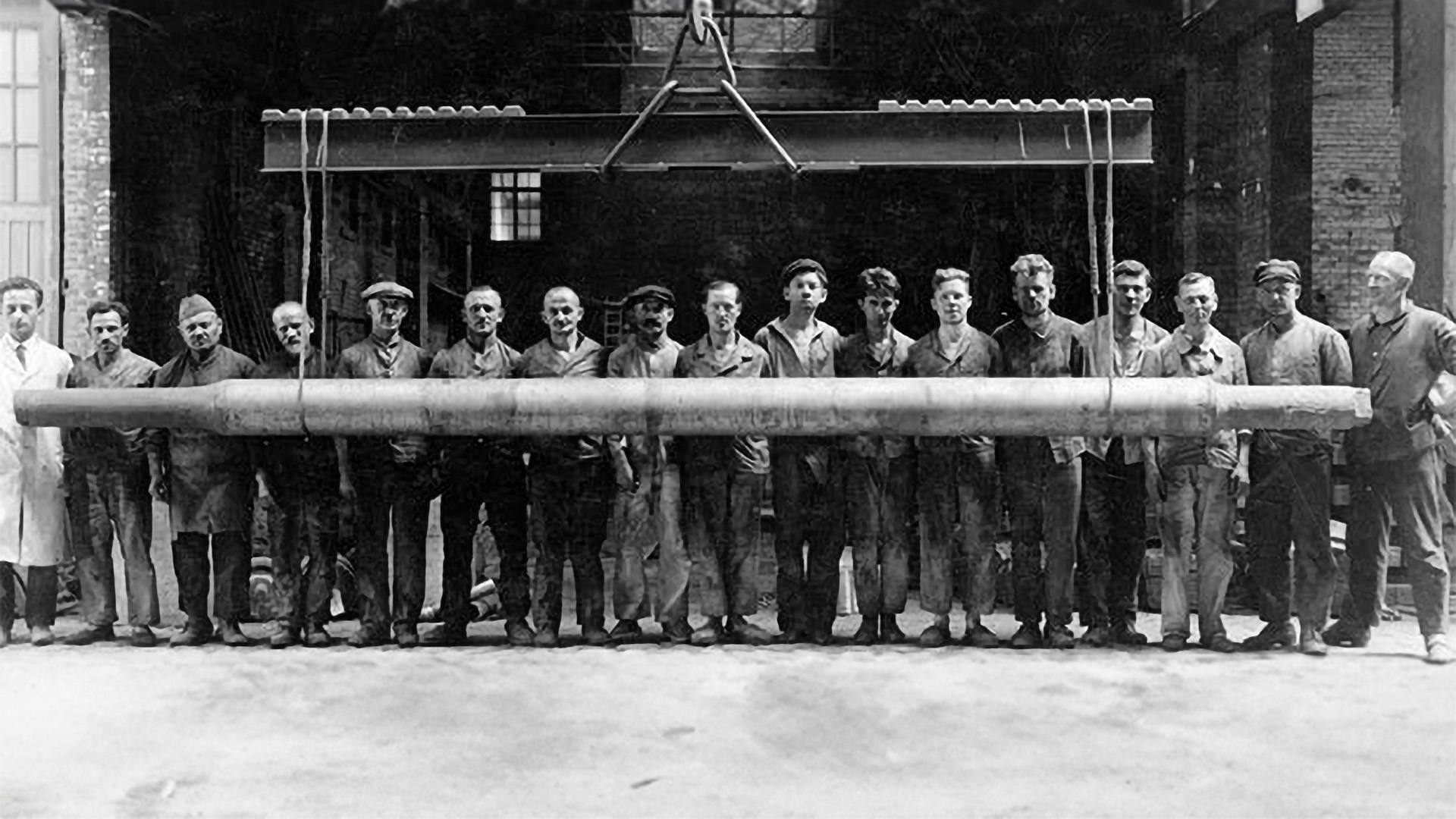

Casting of mixing, calender and milling rolls for the rubber, paper and food industries with excellent quality and export to many European countries

1914

Development of the world's first hot blast cupola furnace by company founder Eduard Schürmann

1895

After 3 years of construction, the first melt for the production of chilled cast iron, primarily for the railroad industry, as well as hand mould gray cast iron for mechanical engineering

1892

Eduard Schürmann founded the company Eisenwerk Coswig